RESIN FLOORS - BREATHABLE

It has the feature to let pass rising damp and remain perfectly anchored to the substrate. Prima Pavimenti, before proceeding with the resin coating, always evaluate the ascent moisture amount, to propose the most suitable solution to the specific situation.

Often, we are faced with customers who tell us that the resin floors “come off” in some areas due to a miscalculation of the moisture component.

The moisture creates a counterforce against which leads to “bubbles” formation on the resin coating; subsequently the bubbles break and become areas of peeling flooring.

The vapor barrier (a sheet of polyethylene placed under the screed) applied on new construction screeds eliminates the problem of rising damp, but it is not often present on old supports.

Depending on the amount of moisture present, different solutions are adopted. Steam-permeable, solvent-free systems for industrial floors with high mechanical strength, wear and abrasion with different technical characteristics and thickness depending on presence or absence of a vapor barrier and/or where there is evidence of damp spots.

The transpirable epoxy multilayer resin systems are suitable for coating fresh concrete (after only 4 days of maturation) or very moist surfaces so as not to accumulate the damp between the support (often in concrete) and the floor.

Technical solutions

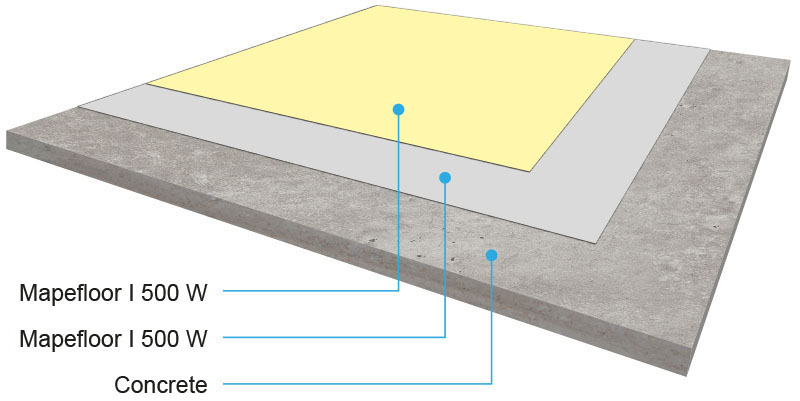

VAPOUR PERMEABLE EPOXY SYSTEM

1. Mechanical preparation of the support.

2. First hand of epoxy resin, applied by spatula; sanding with quarz on fresh.

3. Last hand of epoxy resin, applied by spatula. RAL colour.

Multi-layers resin system, solvent free. Permeable to vapour. It is intended for floor without vapour barrier, or for new concrete floor after few days from installation: almost 4 days. Useful to create a not-slepery surface with a more or a less evident effect. Thickness around 1,5 mm. It presents hight values of mechanical and chemical resistence. It is intended for industrial floors subject to medium traffic.

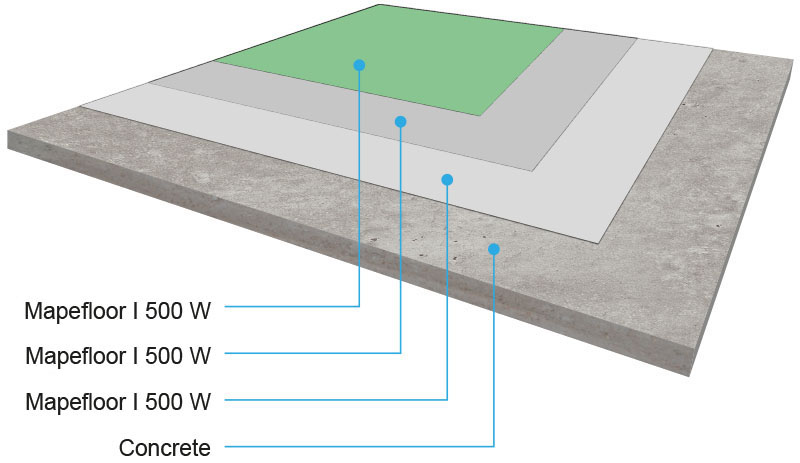

VAPOUR PERMEABLE EPOXY SYSTEM

1. Mechanical preparation of the support.

2. First hand of epoxy resin, applied by spatula; sanding with quarz on fresh.

3. Second hand of epoxy resin, applied by spatula; sanding with quarz on fresh.

4. Third hand of epoxy resin, applied by spatula; sanding with quarz on fresh.

5. Last hand of epoxy resin, applied by roll. RAL colour.

Multi-layers resin system, solvent free. Permeable to vapour. It is intended for floor without vapour barrier, or for new concrete floor after few days from installation: almost 4 days. Useful to create a not-slepery surface with a more or a less evident effect. Thickness around 1,5 mm. It presents hight values of mechanical and chemical resistence. It is intended for industrial floors subject to medium traffic.

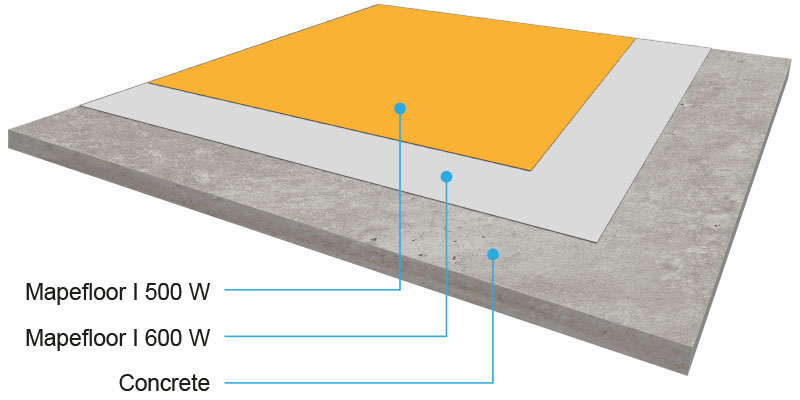

SELF-LEVELLING VAPOUR PERMEABLE EPOXY SYSTEM

1. Mechanical preparation of the support.

2. First hand of epoxy resin, applied by spatula; sanding with quarz on fresh.

3. Second hand, self levelling hand, hight thickness epoxy resin, applied by spatula. RAL colour.

4. Last hand of epoxy transparent resin, applied by roll. RAL colour.

Self levelling resin system, solvent free. Permeable to vapour. It is intended for floor without vapour barrier, or for new concrete floor after few days from installation: almost 4 days. Useful to create a not-slepery surface with a more or a less evident effect. Thickness from 2 to 4 mm. It presents hight values of mechanical and chemical resistence. It is intended for industrial floors subject to hight traffic. Nice natural aesthetical effect.

HAI UNA RICHIESTA?

HAI UNA RICHIESTA?