Rely on PRIMA PAVIMENTI, the sector professionals

to satisfy every customer need.

SELF-LEVELLING COATINGS

Fill out the form and you will be contacted by one of our representatives.

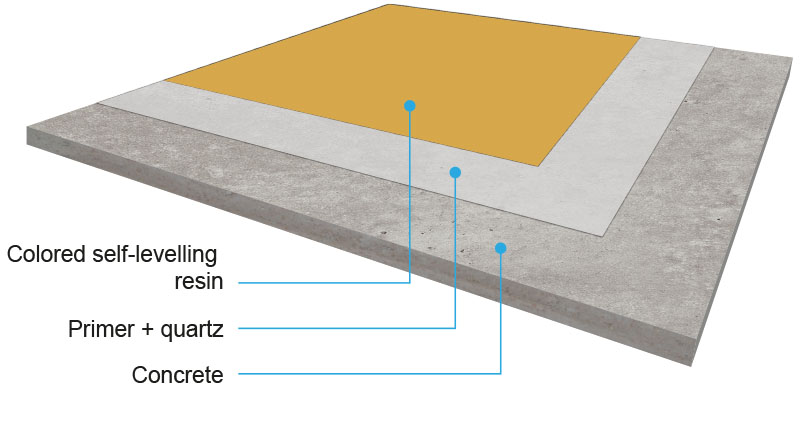

1. Mechanical preparation of the support.

2. First hand of epoxy resin, applied by spatula; sanding with quartz on fresh.

3. Application of self-levelling resin in Ral colour.

Self-levelling epoxy system with high solids content for industrial floors from 2 to 4 mm thick, with high chemical resistance, impermeable to oils and aggressive agents, resistant to frequent washing. Suitable for medium-heavy traffic industrial flooring where a smooth surface is required, such as trilateral forklift lanes, warehouses, storage areas, pedestrian and transit areas of forklifts, schools, offices, exhibition centers, showrooms.

Related systems

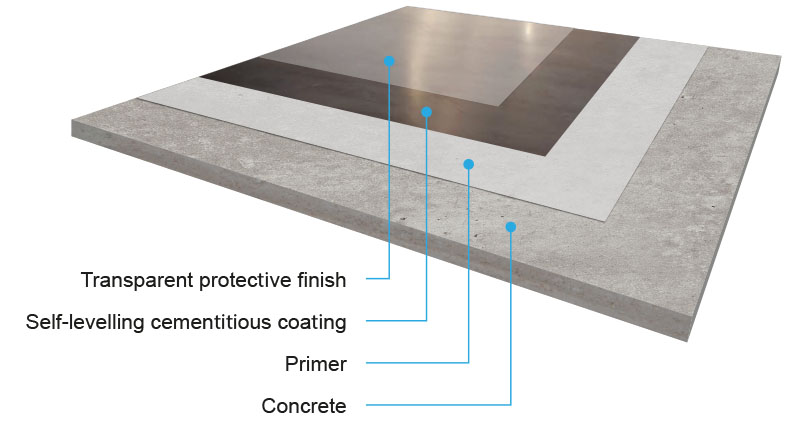

1. Mechanical preparation of the support.

2. First hand of epoxy resin, applied by spatula; sanding with quartz on fresh.

3. Self-levelling cementitious coating.

High thickness resin-cement self-levelling coating, average thickness between 5 and 30 mm; ultra-fast drying (5 hours). Provides a floor with high mechanical resistance. Suitable for all environments where you need a durable, smooth, seamless floor is required. It is the best solution for high-density handling operaons, ideal for vertical storage systems with three-way shuttle or AGV shuttle handling.

Related systems

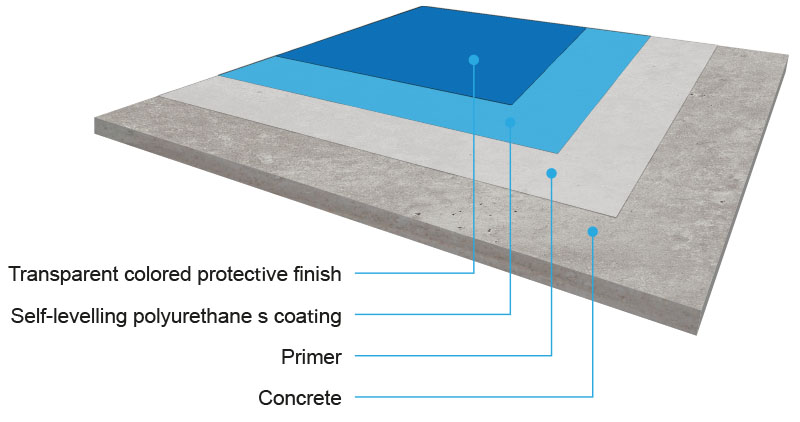

1. Mechanical preparation of the support.

2. First hand of epoxy resin, applied by spatula; sanding with quartz on fresh.

3. Polyurethane self-levelling coating.

4. Transparent protective finish

It is a system based on aliphatic polyurethane resin, self-leveling, smooth and colored, elastic, characterized by a good aesthetic appearance. Suitable for the production of resin coatings with a thickness of 2 mm. Used as floor coverings in civil and tertiary environments such as hospitals, museums, shops, schools, kindergartens, apartments, etc. The transparency of the finish allows to realize particular aesthetic effects in the base resin layer (e.g. sowing of colored chips, chromatic mixtures obtained by the use of different colors, etc.).

Related systems

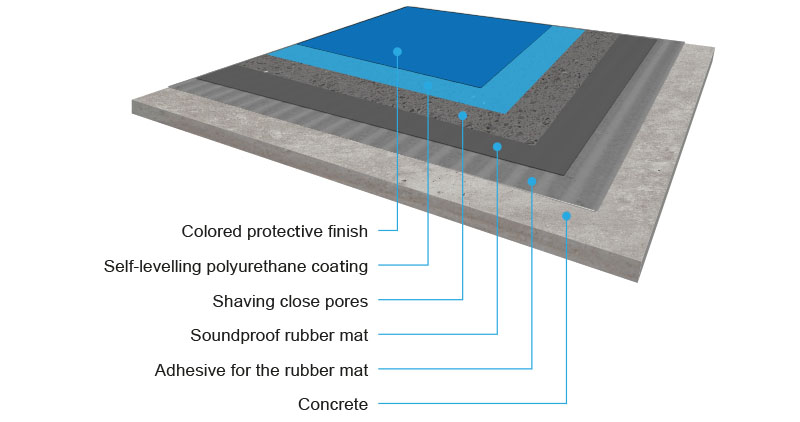

1. Mechanical preparation of the support.

2. Application of adhesive for the rubber mat.

3. Thorough laying of the rubber mat.

4. Finishing the mat and saturating the pores.

5. Polyurethane self-levelling compound in RAL colour.

6. Transparent protective top coat

This is an aliphatic, self-levelling, smooth and coloured polyurethane resin-based system with a good aesthetic appearance. Equipped with a matress of flexible and elastic rubber granules, which gives it a high level of comfort in use, thanks to its sound-absorbing characteristics. Suitable for resin floor coverings with an average thickness of 6 mm. Ideal for flooring in civil and tertiary sectors such as hospitals, museums, conference halls, shops, schools, kindergartens, etc.

Related systems

HAI UNA RICHIESTA?

HAI UNA RICHIESTA?