RESIN FLOORS - TOP SOLUTION

Resin is a very versatile product, nowadays increasingly chosen thanks to its high performances. It excellently responds to specific needs of each sector, both in terms of performances and functionality and aesthetic appearance.

Selected by architects and interior designers, for their aesthetic and emotional features.

Continuous research and attention to innovation led us to offer more and more tech solutions, highly customizable and eco-friendly (polluting and solvent-free materials respecting our environment and health).

Available in multiple formulations and combinations, they respond positively to the high standards required by our customers. They guarantee chemical resistance or wear, conductivity or elasticity, easy sanitizing and maintenance, durability, continuous and hygienic surfaces, in compliance with regulations related to each industrial branch.

Resin is the most suitable material for newly or heavily damaged floors requiring functional recovery or renewal, considering that our intervention or maintenance work may be minimally invasive and execution times are short, representing a clear advantage for our customer.

Technical solutions

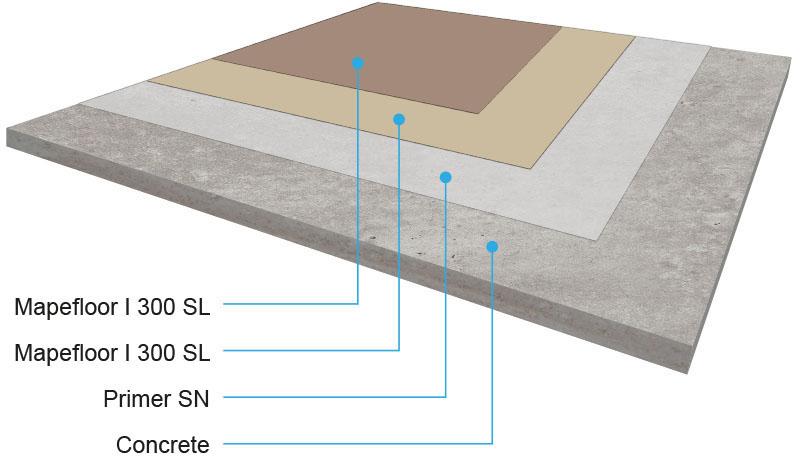

EPOXY MULTISTRATE

1. Mechanical preparation of the support.

2. First hand of epoxy resin, applied by spatula; sanding with quarz on fresh.

3. Last hand of epoxy resin, applied by spatula. RAL colour.

Multi-layers resin system, solvent free; useful to create a not-slepery surface with a more or a less evident effect. Thickness betwenn 0,8 to 1,2 mm. It presents hight values of mechanical and chemical resistence. It is intended for industrial floors subject to light traffic.

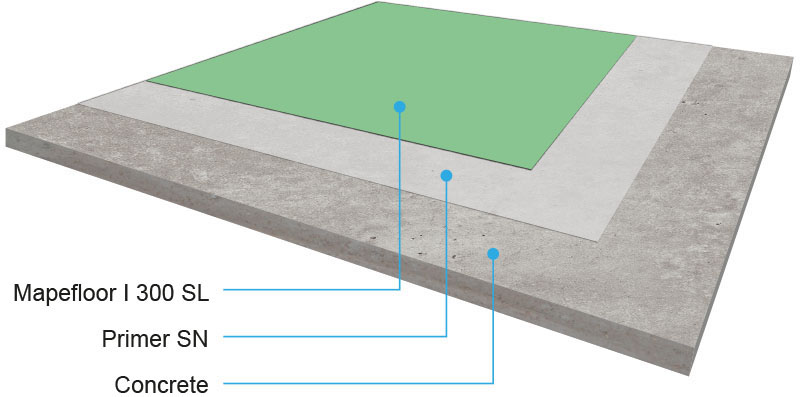

SOLVENT-FREE, MULTI-LAYER EPOXY SYSTEM

1. Mechanical preparation of the support.

2. First hand of epoxy resin, applied by spatula; sanding with quarz on fresh.

3. Second hand of epoxy resin, applied by spatula; sanding with quarz on fresh.

4. Last hand of epoxy resin, applied by spatula. RAL colour.

Multi-layers resin system, solvent free; useful to create a not-slepery surface with a more or a less evident effect. Thickness betwenn 1 to 4 mm. It presents hight values of mechanical and chemical resistence. It is intended for industrial floors subject to heavy traffic.

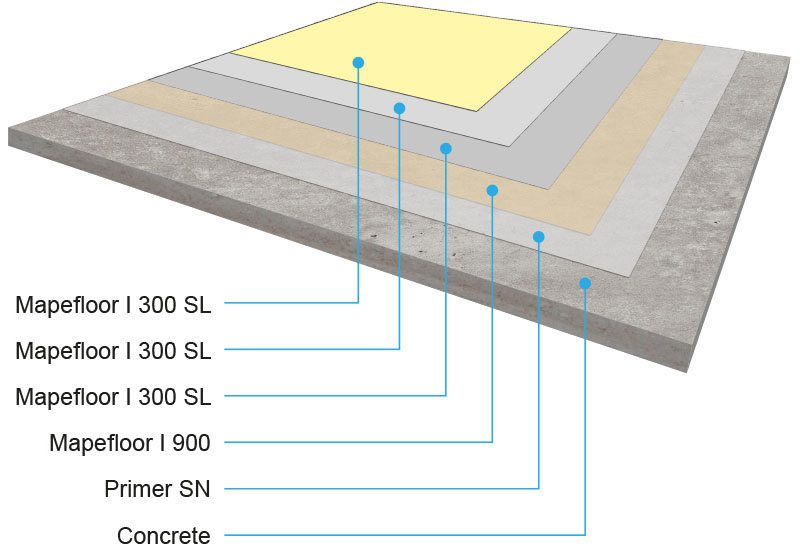

EPOXY MORTAR SYSTEM

1. Mechanical preparation of the support.

2. First hand of epoxy resin, applied by roll.

3. Second hand of epoxy mortar (mix of resin and quarz), applied by screed.

4. Impregnation of the mortar with epoxy resin.

5. Hand of epoxy resin, applied by spatula; sanding with quarz on fresh.

6. Last hand with epoxy resin, applied by spatula. RAL colour.

Hight thikness resin system, solvent free. Thickness betwenn 0,5 to 1,5 mm. Finishing: smooth or not-slepery (with a more or a less evident effect). It is intended to repair very ruined industrial floor. It presents hight values of mechanical and chemical resistence. It is intended for industrial floors subject to very heavy traffic.

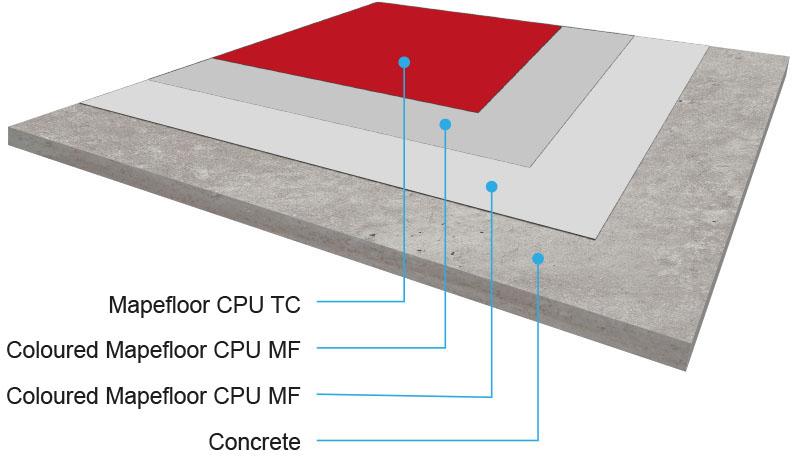

POLYURETHANE CEMENT-BASED SELF-LEVELLING MORTAR

1. Mechanical preparation of the support.

2. Trmming through coloured cement-polyurethane resin dusted with ductile quartz.

3. Second trimming through coloured cement-polyurethane resin dusted with ductile quartz.

4. Last trimming through coloured cement-polyurethane resin.

Polyurethane-cement resin, free-solvent, suitable for realizing 4-mm average-thick resin floor coverings. It has high chemical and mechanical resistance, as well as resistance to shock caused by frequent hot water washing – up to 80°c. It is suitable for food processing companies. Smooth or slip resistant finishing.

POLYURETHANE-CEMENT-BASED MORTAR

1. Mechanical preparation of the support.

2. Coloured cement-polyurethane resin application through spatula and strip light.

Cement-polyurethane resin, solvent-free, suitable for realizing 10-mm thick resin floor coverings. It has high chemical and mechanical resistance. It is slip-resistant and thermic-resistant, as well as resistant to shock caused by frequent hot water and steam washing – up to 180°c. It is indicated for refrigerating rooms and food processing companies.

SELF-LEVELLING SYSTEM

1. Mechanical preparation of the support.

2. Trimming through epoxy resin with ductile quartz.

3. Self-levelling cement.

Resin-cement self-levelling floor covering, high thickness – on average 5 to 30 mm – ultra-rapid hardening (5 hours). It permits to obtain high mechanical-resistant floors. It is indicated in rooms where a flat, jointless and resistant floor is required. It it the best solution for high-movement activities as well as in vertical warehouses where trilateral trolleys and agv shuttles are used.

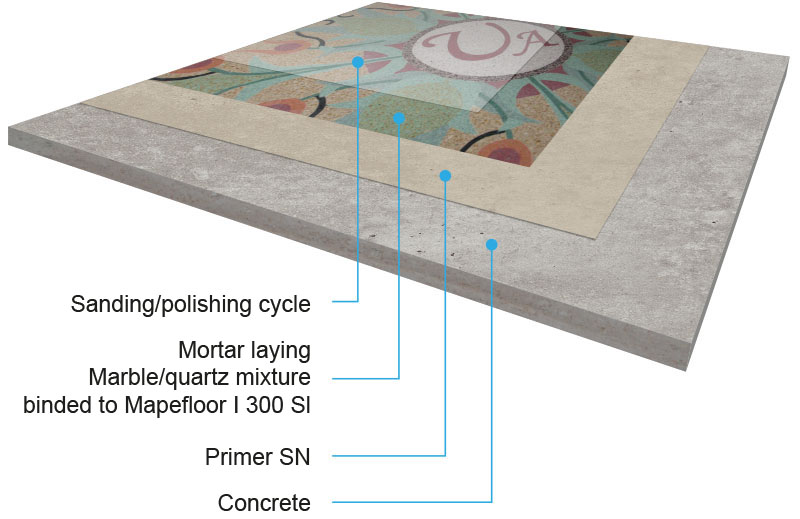

MAPEFLOOR SYSTEM 35 is a Terrazzo seamless system composed by the specific epoxy binder, 10 mm thickness about, to be mixed with special epoxy aggregates of different colours, dimensions and nature.

Suitable to different uses to decorate shopping malls, showrooms, schools, museums, theaters, restaurants, bars, representative offices, shops.

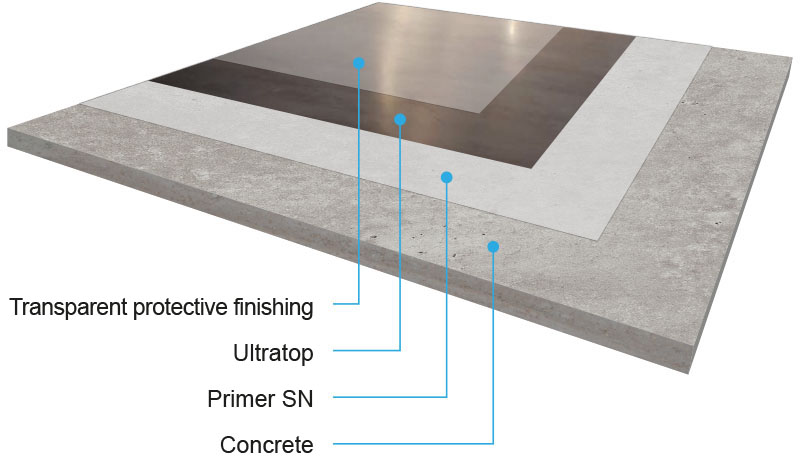

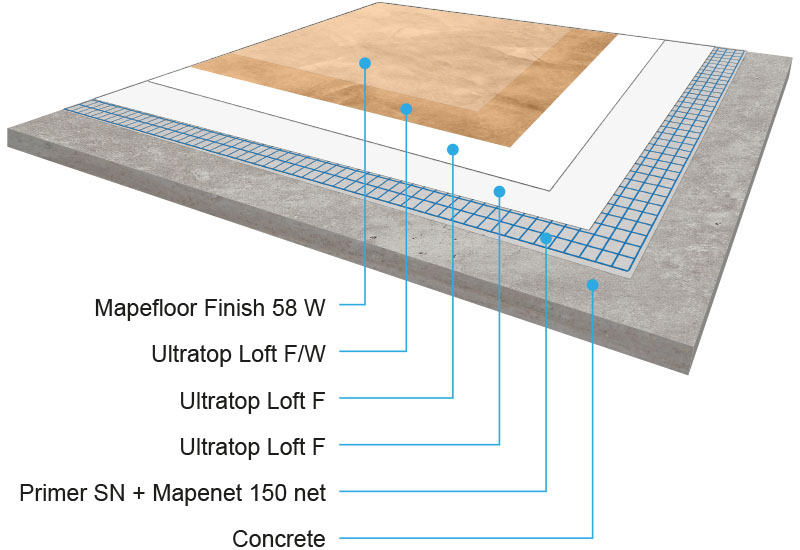

CEMENTITIOUS PASTE WITH A TROWELED OR MOTTLED EFFECT

Ultratop Loft F is the ideal coating product to create decorative interior floors and walls with a pronounced materic effect. Thanks to its ease of use, versatility and its resistance to abrasion, this product is ideal for creating floors subjected to intense pedestrian traffic in areas such as shops, restaurants, reception areas, private homes, cafes, hotels and showrooms, and generally in all areas relating to interior decorating in the civil building sector. The consistency of the product, reduced thickness of the layer applied, the possibility of being-applied also on vertical surfaces and of combining it with a various range of colours, allows an infinite variety of original and unique coatings to be created.

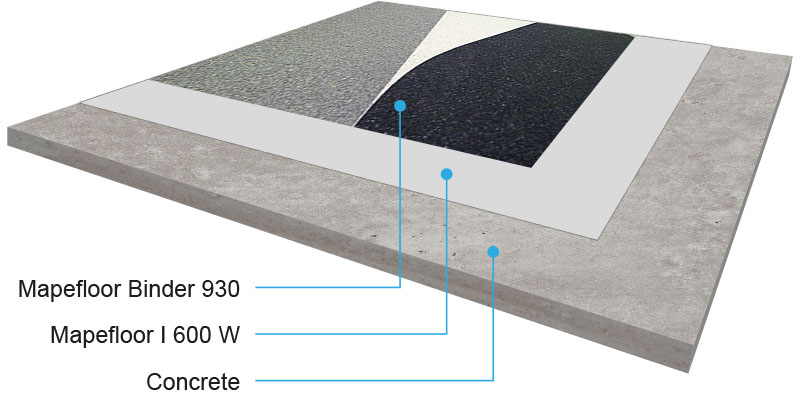

ONE-COMPONENT ALIPHATIC POLYURETHANE BINDER

Mapefloor Binder 930 is a one-component, solventfree, moisture-curing, non-yellowing, transparent aliphatic polyurethane binder. When mixed with natural aggregates, such as marble, stone or quartz, it is used to form self-draining flooring suitable for internal and external environments. When Mapefloor Binder 930 is mixed with singlecoloured or multi-coloured assorted aggregates, it is used to create unique flooring with multi-coloured effects in an unlimited variety of geometric patterns.

HAI UNA RICHIESTA?

HAI UNA RICHIESTA?