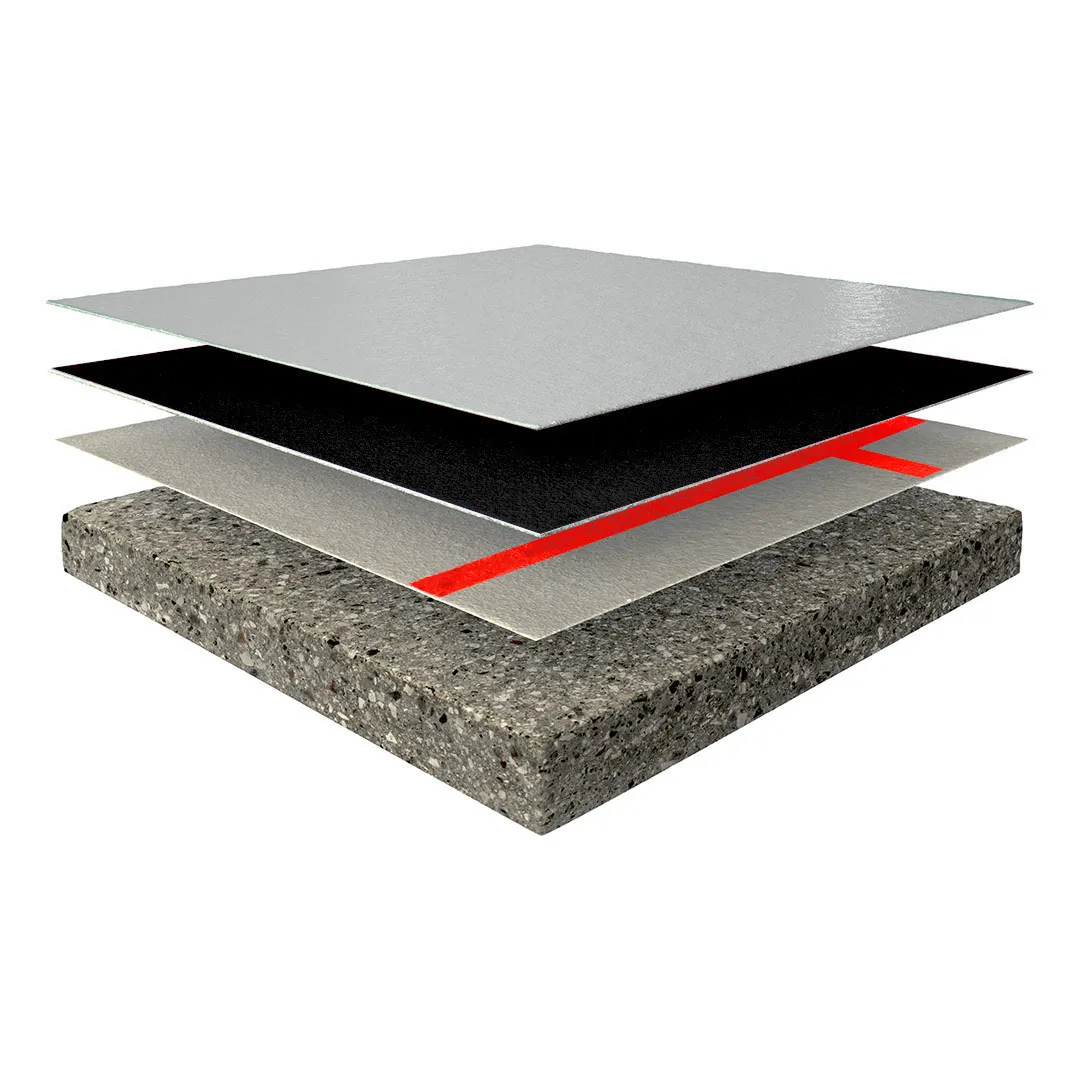

Self-levelling epoxy system with for antistatic, conductive industrial floors; thickness 1.5 to 2 mm

Selflevelling epoxy system used to form anti-static conductive industrial floors which are highly resistant to chemicals and physical aggression, waterproof, impermeable to aggressive substances and liquids in general.

It is easy to wash and sanitise. Its quick application reduces plant downtime..

Technical solution

Mapefloor System AS

ADVANTAGES

Safety for operators and productsi

Safety for operators and productsi Dustproof and waterproof

Dustproof and waterproof High resistance to wear and abrasion

High resistance to wear and abrasion Chemical resistance

Chemical resistanceintended use

- Electronics industries

- Flammable warehouses

- Clean rooms and hospital wards

- Pharmaceutical industries

- Data centres

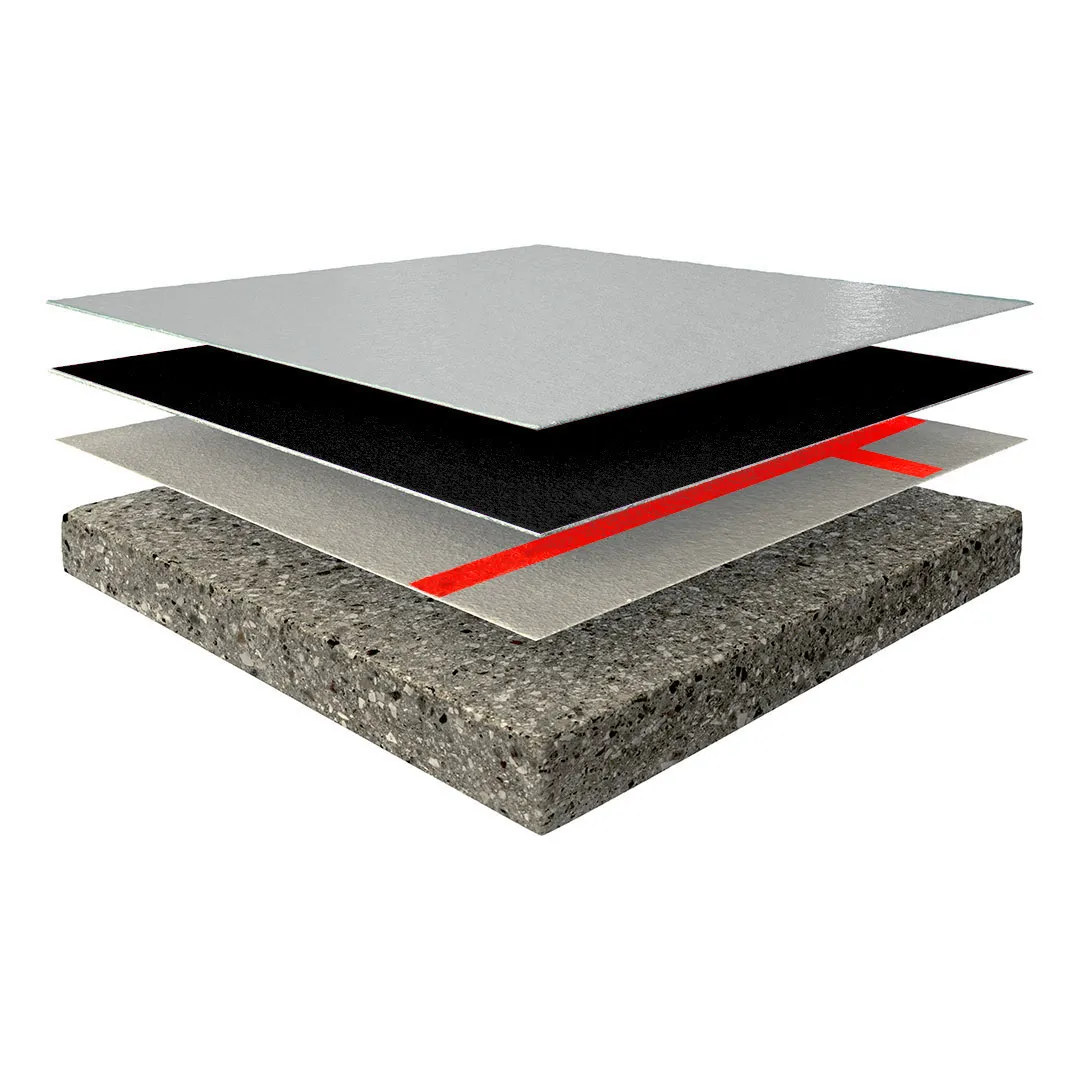

Two-component, self-levelling epoxy formulation used to form electrically conductive resin systems according to ESD requirements

This electroconductive, self-levelling epoxy system guarantees antistatic industrial flooring with high chemical and mechanical resistance. It is waterproof and can withstand frequent washing, making it ideal for critical environments such as clean rooms, hospitals, and the pharmaceutical and electronics industries. The coating has an attractive appearance and a smooth finish. The speed of application reduces intervention times and, consequently, plant downtime.

Technical solution

Mapefloor System ESD

ADVANTAGES

Good chemical resistance

Good chemical resistance Waterproof

Waterproof Dustproof

Dustproof Easy to clean

Easy to cleanintended use

- Electronics companies where performance in accordance with ESD standards is required

- Chemical and pharmaceutical industries

- Laboratories

- Hospitals and operating theatres

- Automotive industry

- Aerospace industry

- Sterile environments

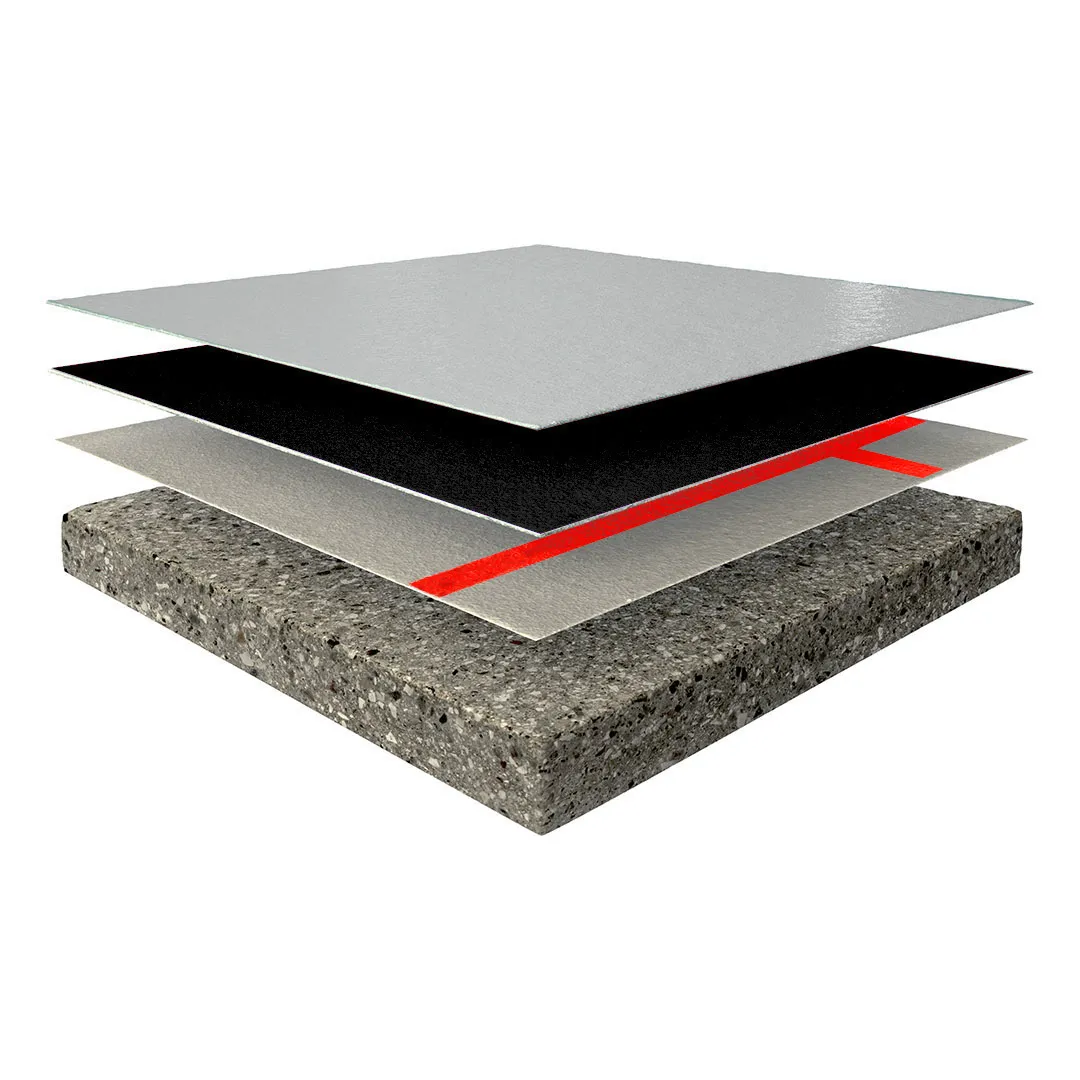

Self-levelling epoxy system for antistatic, dissipative industrial floors, thickness 1.5 to 2 mm

This is a self-levelling epoxy system with a high solids content, designed for creating antistatic, dissipative industrial flooring in environments where electrostatic control is required. The coating has a smooth, attractive finish. Its quick installation reduces intervention times and, consequently, plant downtime.

Technical solution

Mapefloor Compact System EDF

ADVANTAGES

Electrically dissipative

Electrically dissipative Dustproof and waterproof

Dustproof and waterproof High resistance to wear and abrasion

High resistance to wear and abrasion Resistant to most aggressive chemical products

Resistant to most aggressive chemical productsintended use

- Electronics industries

- Flammable storage facilities.

- Clean rooms

- Hospitals and operating theatres

- Pharmaceutical industries

- Automotive industry

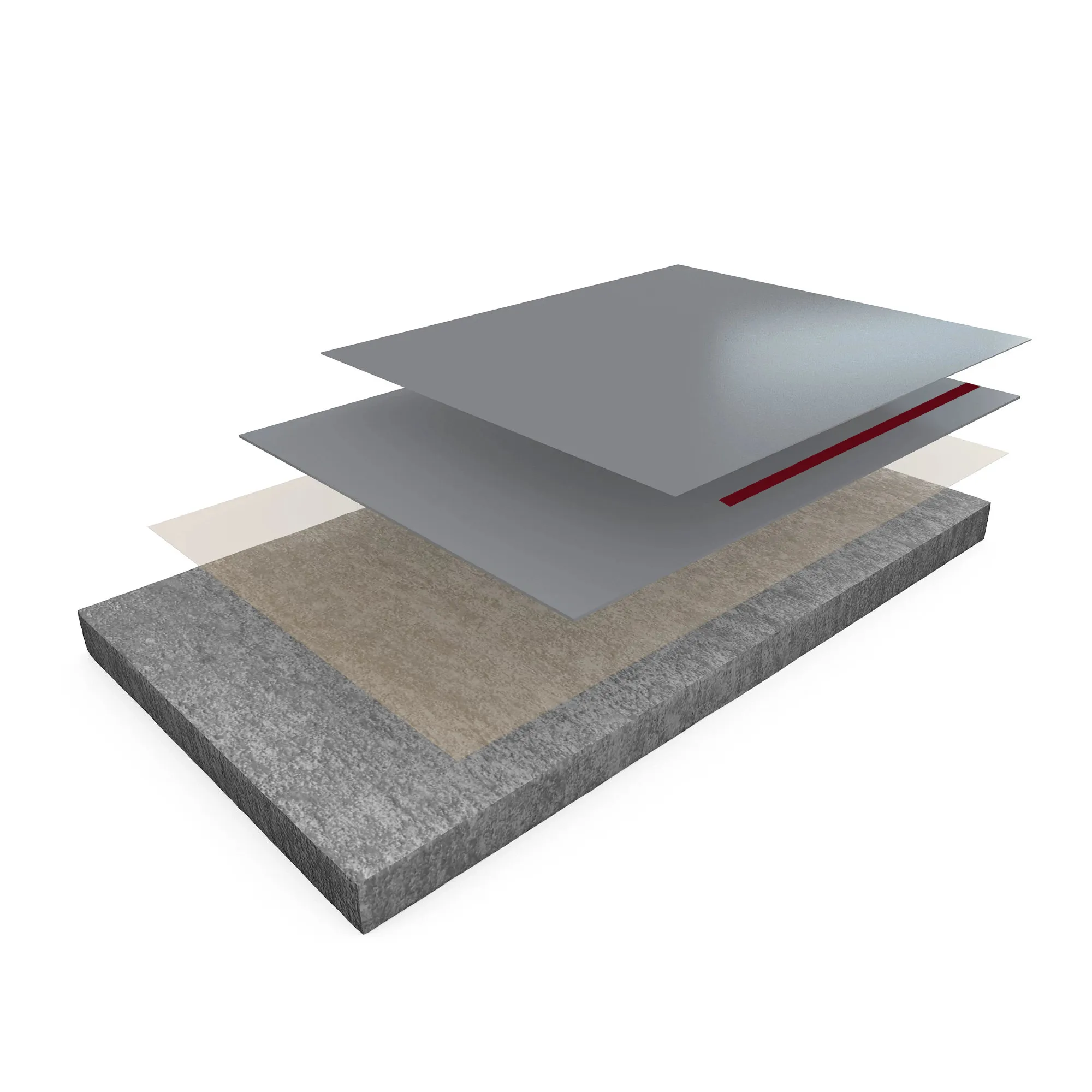

Self-levelling two-component epoxy formulation for electrically conductive coatings

Resuflor Topcoat SDU EV is a unique epoxy resin-based coating system with a static-dissipative urethane finish.

The system offers a highly durable satin finish with high resistance to chemicals. Thanks to its combination of ESD performance and

7-day resistance to NMP, it is specifically designed for battery manufacturing facilities.

Soluzione tecnica

RESUFLOR TOPCOAT

SDU EV

Vantaggi

Resistenza di 7 giorni all’N-metil-2-pirrolidone (NMP)

Resistenza di 7 giorni all’N-metil-2-pirrolidone (NMP) Resistenza di 14 giorni al dimetilcarbonato (DMC)

Resistenza di 14 giorni al dimetilcarbonato (DMC) Include una barriera di protezione dal vapore acqueo che

Include una barriera di protezione dal vapore acqueo chelo rende rapido da installare e ideale per le dry room

Elevata resistenza agli agenti chimici

Elevata resistenza agli agenti chimicidestinazione d’uso

- Stabilimenti di produzione batterie